PWM (Pulse Width Modulation)

🟠 How to handle pulse width modulation

PWM (pulse width modulation) is used to control the power supplied to the load.

🔸 Classic method - reducing the voltage through a rheostat or potentiometer.

🔻 Disadvantage: inefficient, since part of the energy is lost as heat.

🔸 PWM method - supplying voltage in short pulses with a fixed amplitude.

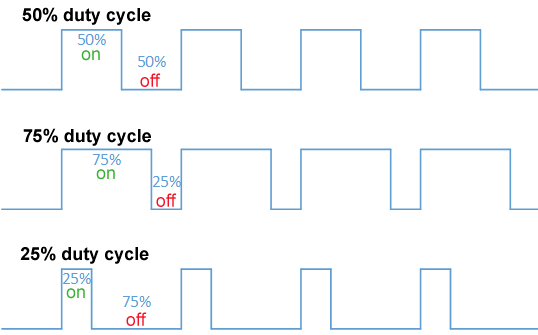

Instead of changing the voltage, the duty cycle changes:

- More on time → more power

- Less on time → less power

This control method is efficient and causes almost no losses.

Brief

- mainly used to control the power supplied to the device.

- in some cases it can be used to transmit information for configuring the device.

- has a low power loss and the ability to digitally/software control.

It has 2 main parameters

- Frequency (switching frequency,

Hz), - Duty cycle (percentage of time in "HIGH" state, from

0%to100%).

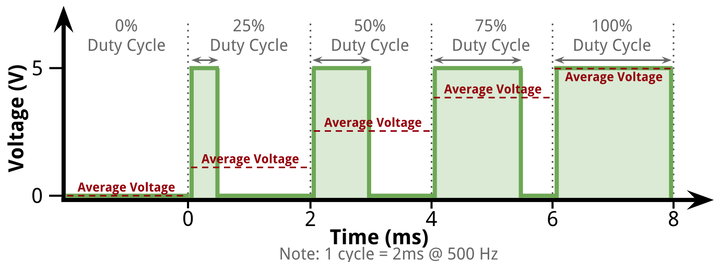

Duty cycle

- Percentage of time during which the signal is active

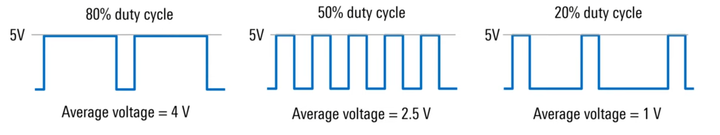

- signal with 20% duty cycle is active 20% of the time

- signal with 50% duty cycle is active 50% of the time

- signal with 80% duty cycle is active 80% of the time

- The duty cycle can be set or controlled in

3 main ways- Manual method (Use various knobs or sliders)

- Automatic (for example, using feedback on the output voltage in a pulse power supply)

- Software (using some kind of intelligent system that changes the pulse width depending on external logic or parameters)

Average voltage level

PWM - often used to vary power by changing the average voltage level across a load.

- average load =

peak voltage(5V) *duty cycle(20%) = 1V

Switching Frequency

- Switching frequency, which is defined as the reciprocal of the time between the leading edges of the voltage pulses.

- The required switching frequency depends on the load or application area

- can be from

10Hz to severalkHz - for applications where faster or more precise control is required - higher switching frequencies are used

- but in most applications the switching frequency is fixed

- can be from

- Signals can have the same duty cycles, but different switching frequencies

Examples of PWM Systems

| System | Description |

|---|---|

| 1. Visual Devices | ● Screen brightness control (high frequency to avoid flickering) ● RGB LED color control |

| 2. Audio | ● Digital to analog conversion via filtering ● Use efficient Class D amplifiers |

| 3. Switching Power Supplies (SMPS) | ● The basis of switching converters ● Use MOSFETs to switch pulses |

| 4. DC Motors | ● Fan or pump speed control ● Lower duty cycle → lower speed ● Inertia smooths out operation |

| 5. Servos | ● PWM sets position, not speed ● Pulse width corresponds to deviation from neutral ● Power is supplied via a separate channel |

| 6. Inverters (DC→AC) | ● Generating an alternating signal from PWM pulses |

| 7. Chargers | ● Charging batteries (including from solar panels) ● PWM regulates average voltage to prevent overcharging and reverse current |

🧱 Embedded Rust approach:

- HAL library (e.g.

stm32f1xx-hal,rp2040-hal,esp32-hal) provides API to peripherals. PWMis usually implemented via timers (TIM).- Each

PWMchannel is assigned aGPIOpin and a timer.

🔨 General flow of creating PWM in Rust

- Access

PWMslices (Slices::new) - Configure

PWM7(it controlsGPIO15pin) - Configure channel B of this

PWM(channel connected toGPIO15) - Connect

GPIO15toPWMas output - In the loop, change the duty cycle value to get the breathing effect

💡 Implementation: RP2040

use rp2040_hal::{self as hal, pwm::Slices};

// PWM Slices Init

let pwm_slices = Slices::new(pac.PWM, &mut pac.RESETS);

// Get 7th slice (controls GPIO 14 (A) and GPIO 15 (B))

let mut pwm_slice = pwm_slices.pwm7;

pwm_slice.set_ph_correct(); // Phase correct mode = smoother signal

pwm_slice.set_top(255); // 8-bit duty cycle precision

pwm_slice.enable(); // enable slice

// Get channel_b from 7th slice

let mut channel_b = pwm_slice.channel_b;

// Make channel_b output to 15th pin

let _pin = channel_b.output_to(pins.gpio15);

let mut duty: i16 = 0;

let mut step: i16 = 1;

loop {

let _ = channel_b.set_duty_cycle(duty as u16);

timer.delay_us(1000);

duty += step;

if duty >= 255 || duty <= 0 {

step = -step;

}

}

🧰 Tips for working with PWM

- Do not exceed the frequency - some devices work up to

1-10 kHz. - PWM resolution depends on the timer (8/10/12/16 bit).

- For multi-channel PWM use different channels of the same timer or timers.

- Use a logic analyzer or oscilloscope for visualization.

- Timers often work asynchronously - glitches at startup are possible.

- For silent PWM (LED) use frequencies >

1 kHz.

Read other posts?